Let’s Talk about Wire

So this is a huge topic and I am going to try and whittle this down slightly, ever so slightly.

There are so many kinds and types of wire. So for this particular discussion, we will discuss the basics of wire, at least as I perceive it to be. I am sure there is much more that I will not touch on in this post but this is the basics.

Basic shapes of wires, boy this took me a hot minute to get when I first started. A lot of it is the lingo (we will go over things like that later). There are 3 most basic wires that a majority of wire wrapping techniques use. There is the round wire (and these are the same basic shapes regardless of the size, meaning the gauge size), square wire and half round wire. I am not going to go over right now what types of wire these wires combined can create like combined twisted wires, hammered wires, or coiled wires. That is a whole nother topic as it is so in depth, you would be reading for days lol.

The higher the number the thinner the wire and the easier it is to manipulate it and the more intricate the design can be. Something I learned the hard way, the thinner and softer the wire the easier it breaks while you are using it. So this is one of the reasons that tension on your wire matters. Yes you want tension but you do not want so much tension that it either warps the wires you are wrapping the wire around (your base wires) or that it snaps the wire you are using. No it will not make you start over but it is a pain pick up where you left off and make it look like nothing happened. (another thing to go over at a later date)

Round wire

This wire, in various gauges, on average from 10ga (gauge) to 32 gauge. This wire is the most common wire and it means that each length of wire no matter the length is perfectly round, like a tube, but it is solid rather than hollow. This is by far the most common wire used in wire wrapping and weaving designs, along with chain link. Daed soft is the most common form of this wire but you can certainly get it in some gauges as half hard wire.

Square wire

This wire, again no matter the gauge (although this tends to come in less availability in many gauges and is also not usually in the same gauges as round wire). Many wire wrapping designs use a general 21gauge square wire. Just like the title of the wire this is square shaped, so it is flat on all 4 sides. The beauty of this wire is that it can be twisted to create a more unique look to your jewelry. (Depending on the wire you use and the tightness of your twist it can be very light catching also). Dead soft is the most common type of this wire.

Half round wire

This is another wire that the availability in various gauges is sometimes harder to come by. That being said, one of the reasons for this is that this wire is generally used to bind wires together. One side of this wire is flat and then the other half is round, so it looks like a tunnel on a walkway or road but full of wire rather than hollow. This usually comes in dead soft wire.

Dead Soft wire

This is the softest version of each type of wire. This will be the easiest to manipulate into twists, turns, spirals and things that require the ability to be changed into designs other than straight. On the flip side of that it is also easier to disfigure if you pull too tight, drop, or accidently bend the wrong way.

Half Hard wire

Now this is a wire that is used for things like memory wire, it is much firmr and generally not used for intricate designs or designs that need to be twisted, turned or spiraled into designs due to the firmness and hardness of the wire. It is much harder to manipulate. I know that many people like it though for things like earring hooks, or jump rings, bracelets, or even like hoop earrings.

Colored Wires (Anything that is not real Gold or Silver or Copper)

This is just something that I have learned with experience. When you buy colored wire you need to know that they make each color of wire in batches. Depending on the company and the popularity they may make a batch daily, weekly, monthly, quarterly or even per year. In any case the color you buy today may be different than the color you buy next time and that is because the die lot they use in each bacth can be just a little different. So the gold you buy this time may be a bright yellow gold and then the next time it may be a bit lighter less yellow gold. Some companies will sell it as bright yellow or light gold, others do not differentiate and you the gold may not match. That is all well and good until you are cutting base wires from one roll of wire and realize you do not have enough, you get out another roll and they do not match and it is noticeable. Maybe you have not used that color in a long time and it has tarnished a bit depending on the kind of wire. (Try running it through a polishing cloth and see if it helps).Thsi kind of wire is also very easy to scratch the color off of and leave tool marks on. Once you scratch the color off there is really nothing you can do or leave tool marks on it. Gold, Silver and Copper, you can use very fine sand paper and take those marks out. Even if it is coated, you can just re-coat it yourself. These are things to keep in mind. Not everyone can buy a large amount of wire at a time so these are things to keep in mind.

Kinds of metal wire

There are so many kinds but here are the basics that most wire wrapping is done with. Keep in mind not all wire twists, bends and works the same even though they are the same gauge. It can vary on the kind of wire, the heat in your hands and the wires conductivity (yes that is a thing, warmer wire equals easier to bend wire).

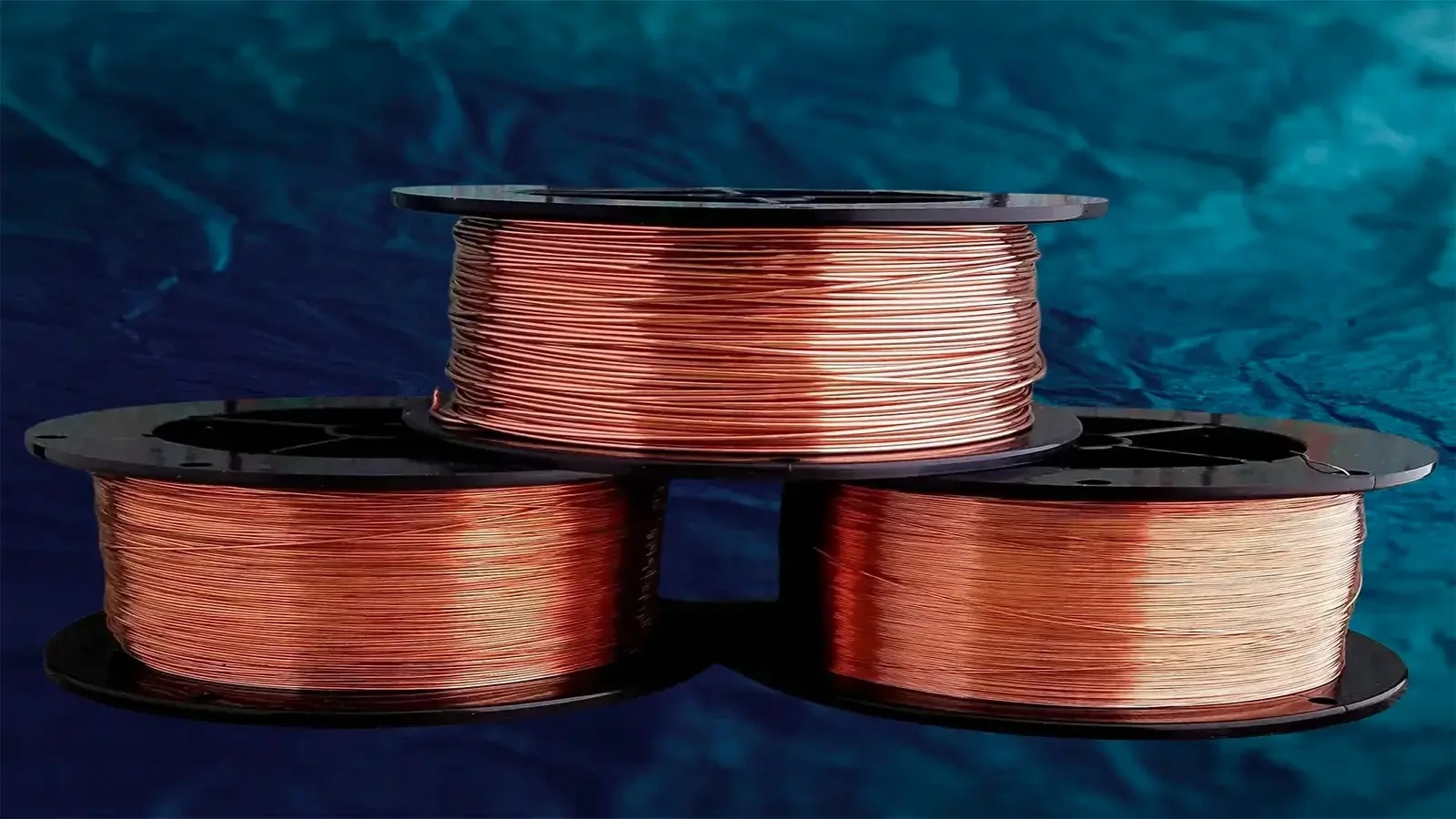

Copper

Now with Copper wire there are actually two different kinds. There is raw copper wire and there is coated copper wire. Raw is just that, it has no coating of any kind on it to protect it from oxidation and I find that it is “softer” than coated. This means that it is easier on the hands to work with, not a huge difference but there is a difference. (Oxidation is what happens to copper after time when it is exposed to the elements, such as oxygen, water, sweat, every day atmosphere, and chemicals of any kind. There is a process of oxidizing your copper jewelry before you sell it and we will talk about that later). You can buy it like this, I have seen many people that have access to electrical wire and they pull the copper wire out of that. Coated copper wire will help it not tarnish or oxidize over time. Now this is not guaranteed as you have no idea what the customer is going to expose it to but it does help. If people buy something that is made with raw copper then they will have to polish it in time to get it back to it’s original color. This also can be coated with color, dozens of colors to include silver, gold, rose gold, etc.

Silver

So there are a few different levels of silver just like there is with gold. All the silvers are soft and easy to work with. I personally find it softer than copper. There is Sterling silver, Argentium silver and .999 silver wire. The most common is Sterling silver wire. Sterling silver can tarnish and needs to be polished and it has a little bit of copper in it. (This is what turns people’s skin green sometimes) You generally will not find coated silver, however you can coat it yourself if you really wanted to. Argentium Silver has germanium in it rather than copper and perhaps a tiny bit of nickel. This does make it a brighter, shinier silver and it is hypoallergenic. Then there is .999 silver and this is the highest grade of silver, very soft and easy to work with and very expensive but beautiful and hard to find.

Gold

Most people are familiar with the types of gold as this comes in Karats. So you have 12,14,18, and 24k gold are the most common wires. Of course these are very expensive to use but they are used for many high end pieces. A way to cut down on the expense of it is that many people use gold filled wire. So you would get it in the karat you want but filled with gold mixed with a base metal to make it stronger and less prone to oxidizing and the gold coming off. It is different from gold plated as that gold can come off very easily from the base metal and then is prone to tarnish and discoloration.

Jewelers Bronze wire

This is a gold toned wire that is a combination of copper and tin, or sometimes copper and zinc. This can tarnish or oxidize but you can also buy it coated or coat it yourself. I do find that different companies offer it and it will come in different colors depending on how they make it with each batch. You can generally find it in several gauges but hard to find it in square or half round gauges as it is not as poloular as many other wires. (That may change as the cost of Gold, Silver and even Copper increases)

Aluminum

Now there are plenty of people that use this wire, due to the cheaper bottom line and it does come in many different colors but it rarely comes in multiple gauges and forms such as square and half round. This is usually anodized or coated and is tarnish resistant. Again it depends on what the wearer exposes it to.

Stainless Steel

I know there are many people that use this for jewelry. It has its advantages, it is resistant to tarnish and rust and can stay very pretty for a very long time. However it is generally much firmer and hard to do any kind of intricate wire wrapping or weaving with it.